Wood Frame Construction

In this article, we are going to talk about the most common construction methods in North America, the wood frame frame construction. We have lots of trees in Canada, so naturally, the cost of wood products is relatively inexpensive. There has been a lot of research on wood as a building material, so we can better understand and utilize this renewable materials.

Wood applications

Wood are often used in buildings less than 4 stories. This is because wood as building materials cannot support its own weight when you stack it up too high. If you have a 6 storey building, you can assume 2 floors are concrete structure at the bottom and the upper 4 storeys are wood. For anything over 7 storeys high, you are looking at a reinforced concrete structure with steel stud interior walls. The construction industry has been trying to push the boundaries of wood.

Wood Frame Construction

Wood frame construction is a construction method to create a wooden skeletal frame for the building that is structurally sound with the minimum material. The initial intent was to aim for using the least amount of wood. At one point in construction history someone realized that wood is not the best thermal insulator, and the voids between the wood is a perfect place for improvement. Wood frame construction use wood for structural support with insulation in between to reduce heat transfer.

Dimensional Lumber nominal size and actual size

The wood are saw to studs of different sizes. We call these “Dimensional Lumber” that comes in a typical of 2×4, 2×6, 2×8, 2×10, 2×12 profile with various lengths of 8’ to 16’ with 2’ increment. Wood are organic material, so they will shrink as moisture decrease. When people are talking about a 2×4 stud, the dimension is actually 1.5” x 3.5”. These shrinkage are proportional, so a 2×8 stud has an actual dimension of 1.5” x 7.25”. You can see that it shrink for an additional quarter inch. The cost for these wood studs increase in price as the size gets larger because it requires a longer time for the trees to grow. Also because they are more rare. A contractor who is trying to save construction cost may connect 2 shorter studs rather than using a whole stud. The inspectors will have to make sure this is done correctly.

| Normal Size | Actual Size |

|---|---|

| 2 x 4 | 1 1/2″ x 3 1/2″ |

| 2 x 6 | 1 1/2″ x 5 1/2″ |

| 2 x 8 | 1 1/2″ x 7 1/4″ |

| 2 x 10 | 1 1/2″ x 9 1/4″ |

| 2 x 12 | 1 1/2″ x 11 1/4″ |

| Notice that the size of the reduction increases as wood length increases | |

Types of wood SPF

The most common type of wood used for dimensional lumber are the SPF. This is not your sunscreen SPF rating, but an abbreviation for Spruce, Pine, and Fir. These softwood have similar properties, so they are often categorized together for construction. Softwood are used during construction for obvious economical reasons. There are also other types of wood such as cedar, cypress, hemlock, and red wood. Framed wood can buckle, twist, and turn. The further apart between studs, the weaker the structure become.

Wall Studs Spacing

It is common practice to have the studs at 16” apart. We call this 16” O/C (16” on centre), which means the studs are measured at the same location.The closer the studs are, the less lateral movement there will be. Between those vertical studs, we can find fire blockings. They prevent fire spread, also, they reduce the chance of vertical stud buckling. When it’s done, we have a series of wood frames. Hence the name “Wood Frame Construction”. Wood studs can be spaced from 16” to 24” apart, but if you want to space the wall studs further apart than 16”, you need to hire a structural engineer to design it accordingly.

Terminology and sizes

Wood frame construction use different sizes of wood for different locations of the structure. For communication purposes, the construction industry has named them differently by location. I have categorized them by location.

Vertical Member

Wall Studs: Typically 2×6 to allow enough space for insulation. Spacing is typically 16” O/C

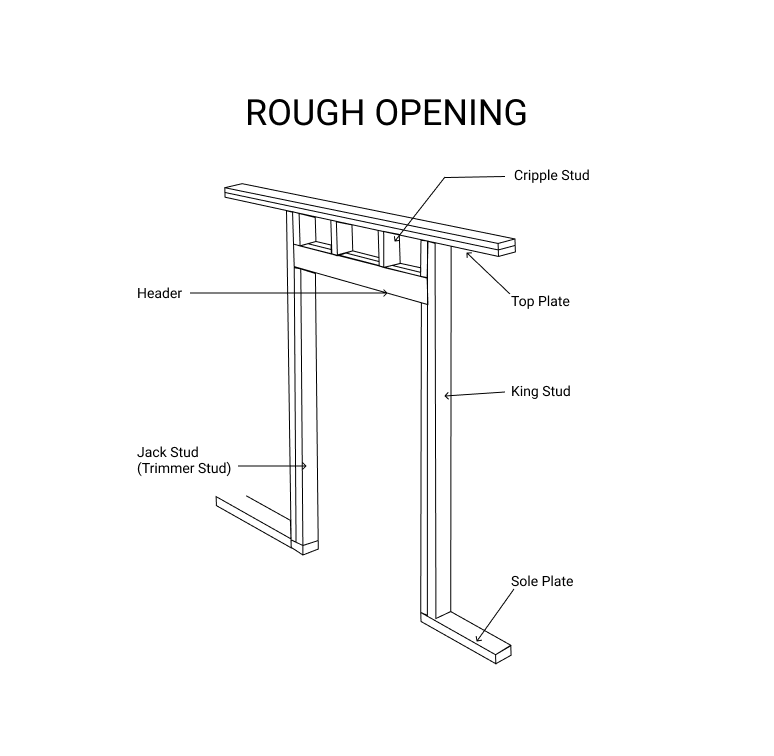

Cripple Stud: When you have an opening in the wall, studs are cut to create the opening. Cripple studs denotes the vertical wall studs below and above the opening. Stud size will match wall stud.

Posts: Posts are made of multiple wall studs attached together. Their purpose is usually to support the beam above. The number of wall studs used to create the post should be the same as the beam. This is to make sure they have the same width to provide proper support. If you see one element wider than the other, it’s a good indication of a poorly designed structural system.

Horizontal Member

Floor Joist: Typically 2×10 because it has to carry weight. The spacing should line up with wall stud to carry the structural load. If located above the top level, it’s called Ceiling Joist.

Bottom plate: Also called sill plate. This is the horizontal member sitting on top of the foundation wall. There should be something between the wood and concrete to prevent water from getting into the wood. Size matching the width of wall stud.

Top Plate: This laid flat above the vertical wall studs. It provides stability to the vertical members. A bearing wall use 2 layers of top plate to spread the load. The size of wood will match the wall stud.

Window Sill: This is located at the bottom of the window. Above cripple studs. The size will match the wall studs.

Lintel: Also called header. This member is like the Top plate laying flat above windows or doors. There is always 2 layers of the lintel to transfer the structural load. The size will match wall studs.

Beam: Beams are very different from the top plate or lintel. They are installed vertically when you look at the profile. The wood studs have the 1.5” side sitting on a post or load-bearing wall. They are usually doubled or tripled studs. This means, you are either looking at a 3” wide beam, or a 4.5” wide beam. This means, it won’t sit flush with your 3.5” or 5.5” wide wall stud. Additionally, beams should be designed by a structural engineer.

Sloped Members

Rafter: Rafters are basically the sloped member on your roof. There are many terminologies for them depending on their location and function. We don’t need to go into details if we are not planning to become a framer. For now, just know that these are used for built-up roof at odd corners. The main roof are now mostly done using Engineered Truss.

Engineered Truss: These are designed by engineers and pre-fabricated in a factory then shipped on site. It includes ceiling joists, and rafters with proper support in between pre-installed.

Inside VS Outside

Without getting into the locations of air barrier, moisture barrier, vapour barrier, and waterproofing membrane, I want to briefly talk about the two sides of the studs. The outside of the studs is usually finished with plywood. We call this the plywood sheathing. Usually, plywood of ⅝” thickness are used. This gives the structure more stability. It also gives the cladding a backing to attach to. The inside of the wood stud is usually finished with gypsum board to be mudded and painted (or wallpapered) to create your beautiful interior.

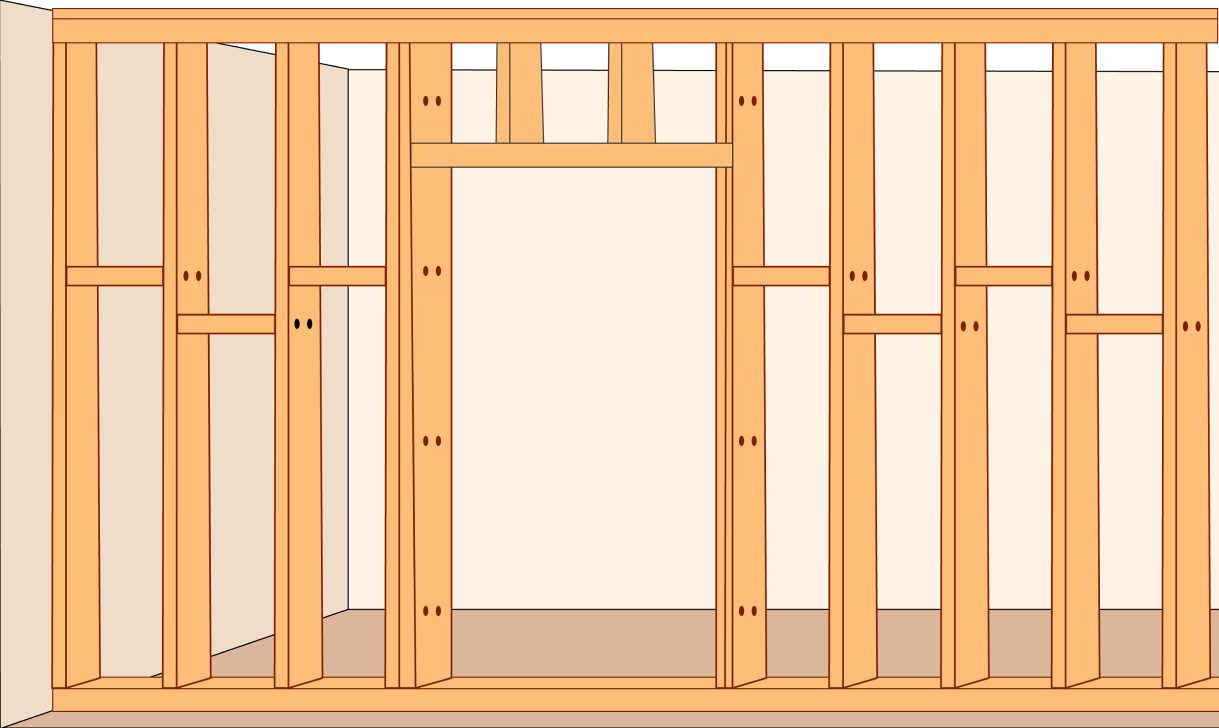

Notice double stud and Lintel at openings

Wood frame construction is just the most common construction method in low rise housing in North America. There are many other construction methods. For example, the basement of low rise housing will be made of reinforced concrete. There are also lath and plaster construction methods on some of the older buildings.